Various Types of Stitches Used in Apparel

Stitch Stitch is very important during manufacturing a garment. Stitch can be defined as, one unit of conformation resulting from one or more strands or loops of thread by intra-looping, inter-looping and interlacing. Stitch quality is measured with stitch size, stitch length, width, depth, tension, sequence, elongation, elasticity, resilience, fabric distortion, yarn severance and abrasive strength. There are six types of stitch, which are deeply discussed in this article.

Some Terminology Related with Stitch:

Interlacing: During stitching when one loop of one thread passes over another loop of another tread is called interlacing

Interlooping: During stitching when loop of one thread passes through the loop of another thread is called interloping.

Intralooping: When a loop one thread passes through the loop of same tread during sewing is called intralooping.

Types of Stitch Used in Garments: Every category of sewing machine produces a specific type of stitch depending on the number of needles, loppers and threads which combine to construct the stitch. Each of these configurations is known as stitch types and they are classified according to their main characteristics There are about seventy (70) types of stitch can be seen in common practice but among them 18 to 20 types of stitch are used in garments manufacturing industries. In tailoring purposes there are only two to three types of stitch are used. All stitches are classed in six (6) groups which are identified by the first of the three digits.

There are different types of stitch used in apparel; those are mentioned in the following:Class-100 (Chain Stitch),Class-200 (Hand Stitch),Class-300 (Lock Stitch),Class-400 (Multi Thread Stitch),Class-500 (Over Edge Stitch),Class-600 (Covering Chain Stitch).All the above types of stitch have discussed in the below: 1. Class-100 (Chain Stitch):

Class-100 named as chain stitch, which is produced by one or more needle threads and are characterized by interloping. In chain stitch, one needle thread is passed through the fabric, form needle loop and is secured by the next loop formed by the same thread. It should be noted that, chain stitch is elastic and thicker than lock stitch and can easily be raveled, where particular care is required to prevent run back from the last stitch. Stitches are formed by intralooping. Each loop is inter connected with same thread.There is no lower thread.The needle carries the thread through the fabric and looper holds the thread to enter as it descends for the next stitch.Security of stitch is very poor, in case of breakage of one stitch, it unravels very easily.One or more needle thread is used for stitch formation.From opposite sides it looks different. Temporary stitching (e.g. basting) or for blind stitching.Uses for button holing, button attaching, hemming

2. Class-200 (Hand Stitch): Class-200 named as hand stitch which is produced from a single thread. This single thread is passed through the fabric from one side to another and the stitch is secured by the single line of thread passing in and out of the garment. Originally made by hand, now can be formed by machine.Looks like domestic hand stitch.It is produced from single thread passed from one side of the material to the other side with each successive penetration of the needle.This type of stitch is formed by special type of needle and sewing machine.Needle is double pointed with Centre eyed.

Fig 6: Class-200 (Hand Stitch)

Uses Hand Stitch

Lapel of jacket, coat and expensive clothes.Lapel: A stripe of cloth is part of the front of the jacket or coat.

Disadvantages Hand Stitch Time consuming process.Higher cost.Speed of sewing m\c is very slow.Rare in use.

3. Class-300 (Lock Stitch):

Class-300 named as lock stitch which is produced with two or more groups of threads and two threads are joined by interlacing. Here, loops of one group are passed through the fabric and are secured by the thread of second group, where one group is referred as needle thread and other as bobbin thread. Class-300 (Lock Stitch) has enough strength and same appearance on both sides.

Lock stitch requires at least two threads to form a stitch, a needle threads that feeds from the top & a lower thread that feeds from the bobbin.Needle threads are passed through the fabric & are interlaced by the bobbin threads.A rotary hook catches the needle threads loop as it passes around the bobbin & interlocks the two threads.Appearance of the lock stitch is similar in both sides of the fabric; it is a special feature.Fine yarn is preferable for this type of stitching.Stitches are secured and security of stitches can be increased by back tacking at starting and finishing ends.Abrasion resistance of lock stitch is better because the stitches are embedded in the fabric.

Uses of Lock Stitch

Joining of facing, collar, pocket & other parts.Specially for top stitching.Both for domestic and industrial purposes.

4. Class-400 (Multi Thread Stitch):

Class-400 named as multi thread stitch which is formed with two or more groups of threads. Here, loops of one group of thread are passed through the fabric and are secured by interlacing and interloping with loops of another group. Among two groups, one group is called needle thread and another group is called looper thread. Multi-thread chain stitch requires one or more needle that form loops as they pass through the fabric and interloop with the looper thread on the underside.Threads are bound tighter by interlacing & interlooping.It looks lock stitch at the top side & double chain at the underside.Looper thread is supplied from cone.Need not back tacking at the starting & finishing ends.

Uses Multi Thread Chain Stitch

Used for long length sewing, heavy fabric sewing such as denim, attaching lace, elastic.

5. Class-500 (Over Edge Stitch):

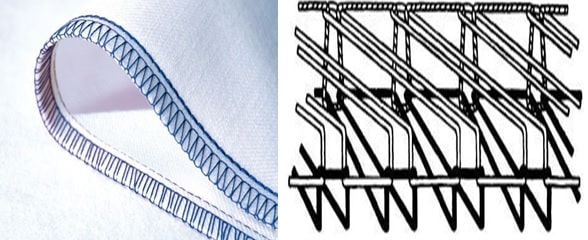

Class-500 named as over edge stitch which is formed with one or more groups of threads. In Class-500 (Over Edge Stitch), one group of thread passes around the edge of fabric so that no thread from the fabric can come out. The most used stitch of this type have one or two needle threads and one or two looper threads and thus forms a narrow band of stitching along the edge of the fabric.

Stitches are formed by two or more group of threads.Formed from one or two needle threads with looper thread.At least one group of threads pass around the edge of the material.Width of the fabric may vary from 3-5 mm.Prevents the fabric from fraying.They have high elasticity.They cannot be unraveled easily.

Fig 9: Class-500 (Over Edge Stitch)

Widely used for knit fabric.Used for decorative purpose.Joining of side seam, armhole of a shirt.Inseam, out-seam of a pant.

6. Class-600 (Covering Chain Stitch):

Class-600 named as covering chain stitch which is produced with three groups of threads. Here, threads of two groups can be seen from either side. In class-600 (Covering Chain Stitch), the first group of thread is called needle thread, second group is called top cover thread and the third group is called bottom cover thread. Three or more sewing thread are used to make this stitch.Three group of sewing thread are used. Such as needle, looper and covering threadSewing thread consumption is very high.This type of stitch are used to join side by side of fabric without increasing thickness.This stitch are used for sewing under wear for attaching lace, braid, elastic etc.

Uses of Covering Chain Stitch Mainly used for knitted apparels.Attaching lace, elastic etc.Decorative purpose in apparels.

Conclusion: All the stitches are used for producing different kind of seam. By this experiment we have learned about different types of stitch and their uses. This knowledge will be helpful in our professional life.